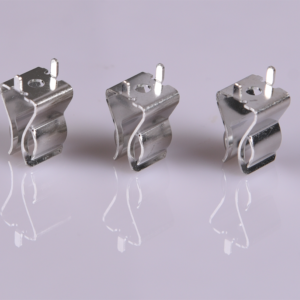

Обзор:

Пружинные металлические зажимы – незаменимые крепежные элементы, известные своей универсальностью и эффективностью в фиксации компонентов. Используемые в самых разных областях, эти зажимы обеспечивают упругое сцепление, гарантируя стабильность и правильное выравнивание соединяемых деталей. Главное преимущество этих зажимов заключается в их пружинных характеристиках, позволяющих им изгибаться и поглощать удары или вибрации, обеспечивая тем самым надежное и прочное соединение. Изготавливаемые методом точной штамповки металла, эти зажимы соответствуют строгим техническим требованиям, гарантируя стабильную производительность и долговечность. Технология штамповки металла позволяет производить высококачественные пружинные металлические зажимы со сложной конструкцией и жесткими допусками, что делает их подходящими для требовательных промышленных и коммерческих применений.

Варианты отделки поверхности:

- Цинкование: улучшает как коррозионную стойкость, так и внешний вид.

- Никелирование: Повышает коррозионную стойкость и увеличивает твёрдость поверхности.

- Порошковая окраска: Обеспечивает прочное, эстетически привлекательное покрытие, защищающее от коррозии и износа.

- Анодирование: в основном используется для алюминиевых зажимов, этот процесс формирует защитный оксидный слой для повышения коррозионной стойкости.

- Пассивация: Применяемая к зажимам из нержавеющей стали, эта обработка удаляет свободные атомы железа, повышая коррозионную стойкость.

Производственный процесс:

- Выбор материала: Выберите подходящий материал, обычно пружинную сталь или нержавеющую сталь, чтобы обеспечить необходимую прочность и упругость зажима.

- Вырубка: Используйте штамповочный пресс для вырезания плоских заготовок из выбранного материала, следуя точным спецификациям по размеру и форме.

- Формовка: С помощью специальных штампов заготовке придаётся V-образная форма, обеспечивая необходимый угол и размеры для её функциональности.

- Термическая обработка: Применить процессы термической обработки, такие как отпуск, для улучшения механических свойств пружинной скобы, повышения ее прочности и упругости.

- Финишная обработка поверхности: Применение методов обработки поверхности, таких как гальванизация, порошковое покрытие или нанесение гальванических покрытий, для повышения коррозионной стойкости и улучшения внешнего вида зажима.

- Контроль качества: Проводить строгий контроль качества на протяжении всего производственного процесса, включая проверку размеров и функциональные испытания, чтобы гарантировать соответствие каждой клипсы отраслевым стандартам и спецификациям.

- Упаковка: Наконец, упакуйте готовые V-образные пружинные зажимы надлежащим образом для отправки, обеспечив их защиту во время транспортировки и готовность к дальнейшему распределению.

Показ Завода:

Мы эксплуатируем широкий ассортимент оборудования и установок, чтобы обеспечить производство продукции высочайшего качества. Наши мощности оснащены 25 штамповочными прессами с усилием от 25 до 300 тонн, высокоточным электроэрозионным оборудованием (EDM), шлифовальными станками, инструментами для сварки и полировки, а также ультразвуковыми системами очистки.

В дополнение к нашим производственным возможностям, мы предлагаем различные процессы металлопокрытия, чтобы улучшить долговечность, внешний вид и функциональность нашей продукции штамповки металла. Среди них: гальваническое покрытие, цинковое покрытие, никелирование, хромирование и анодирование. Наши современные мощности для нанесения покрытий обеспечивают равномерные покрытия, устойчивость к коррозии и соответствие отраслевым стандартам.

Это сочетание профессиональных и автоматизированных производственных линий, передового механического оборудования, строгих мер контроля качества и высококачественных процессов гальванического покрытия обеспечивает поставку штампованных металлических изделий высочайшего стандарта.