О процессе

Штамповка

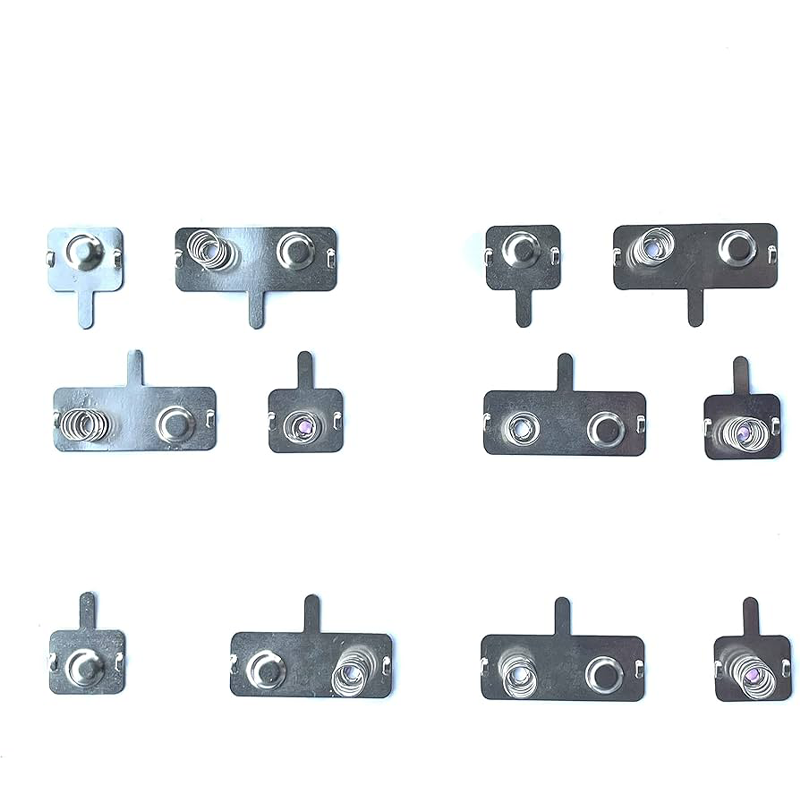

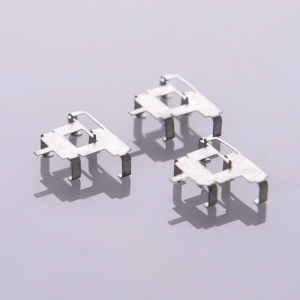

Пружины для батареек и контакты для батареек обычно изготавливаются с помощью процесса прецизионной штамповки. Этот процесс включает размещение металлического листа в штампе, где на него воздействуют высоким давлением, придавая металлу требуемую форму. Этот метод обеспечивает эффективное массовое производство, сохраняя при этом строгие допуски по размерам и высокое качество поверхности.

Прецизионное литье

Для достижения необходимой точности и согласованности пружин и контактов для батарей часто используются технологии прецизионного литья. Тщательно контролируя параметры литья и процессы производства, мы можем изготавливать высокоточные компоненты, которые соответствуют конкретным требованиям к размерам и характеристикам различных типов батарей.

Обработка покрытия

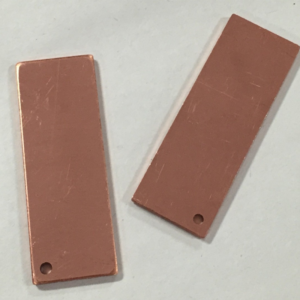

Для повышения коррозионной стойкости и электрической проводимости пружины и контакты батарей проходят обработку поверхностным покрытием. Обычные покрытия включают никелирование и серебрение, которые эффективно предотвращают окисление металла, тем самым продлевая срок службы изделия и обеспечивая стабильную работу.

Специализированные методы обработки

Для приложений, требующих работы в экстремальных условиях, таких как высокие температуры или давление, могут потребоваться специальные материалы и технологии обработки. Эти индивидуальные подходы обеспечивают надежность и стабильность пружин и контактов батарей в сложных условиях.