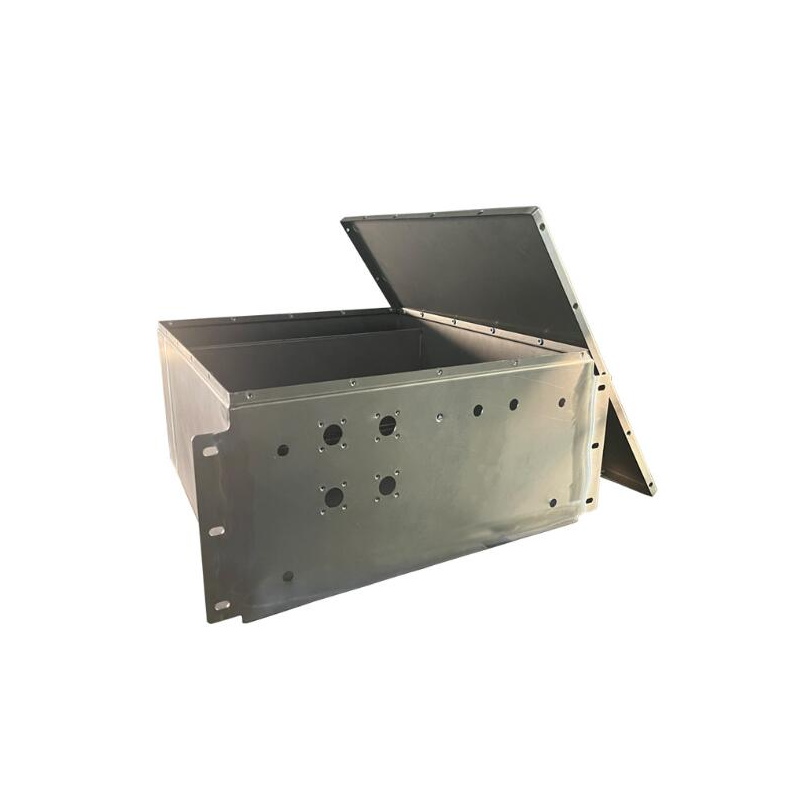

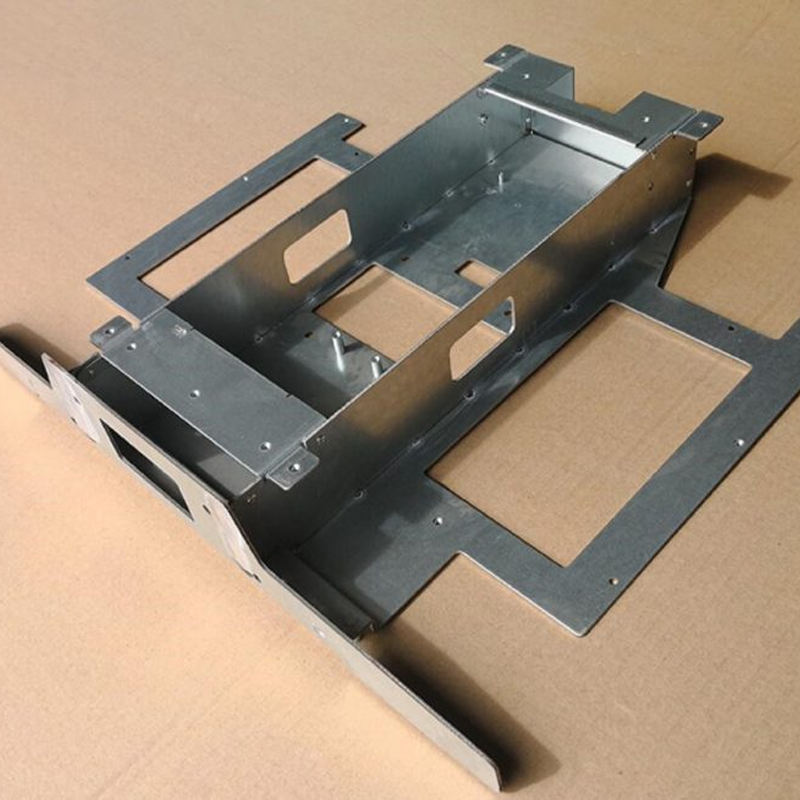

At Plantmetal, we understand that selecting the right steel for your metal stamping projects is crucial to ensuring the success of your production. Metal stamping plays a vital role in a wide array of industries, from automotive parts to electronics enclosures, transforming flat metal sheets into precise, intricate components. The foundation of any successful metal stamping project lies in choosing the correct type of steel, as it directly impacts the performance, durability, and cost-efficiency of the final product.

In this blog post, we will guide you through the process of choosing the right steel for your metal stamping needs, focusing on the key factors that influence this decision. From understanding the various types of steel available to analyzing specific project requirements, this guide will help you make an informed choice for your manufacturing needs.

1. Understanding the Types of Steel for Metal Stamping

The first step in selecting the right steel for your stamping project is to understand the different types of steel available and their unique properties. Each type of steel offers distinct advantages depending on the requirements of your project.

Углеродистая сталь

Carbon steel is one of the most common types used in metal stamping. It is an affordable and versatile choice, consisting primarily of iron and carbon, with trace amounts of other elements. Carbon steel is available in three grades: low carbon, medium carbon, and high carbon. Each grade offers varying properties suited for different applications.

Key Characteristics:

- Low Carbon Steel:Offers good formability and is easier to machine, making it ideal for projects that require high levels of precision and smooth finishes.

- Medium Carbon Steel:Balances strength and flexibility, making it suitable for applications where moderate strength is required.

- High Carbon Steel:Known for its hardness and strength, though it is less malleable and more difficult to work with.

Benefits: Carbon steel is cost-effective, strong, and highly versatile, making it a popular choice for a wide range of metal stamping applications. Low-carbon steel is especially favored for projects requiring excellent weldability, while high-carbon steel is selected for demanding applications that require high strength.

Alloy Steel

Alloy steel is a higher-grade material that includes alloying elements like chromium, nickel, molybdenum, and vanadium. These elements enhance the steel’s overall properties, such as strength, toughness, and wear resistance, making it an ideal choice for demanding applications.

Key Features:

- Composition:Alloy steels contain elements like chromium and nickel to improve hardness, corrosion resistance, and overall strength.

- Properties:Alloy steels can offer enhanced wear resistance and better performance under high-stress conditions.

Advantages: Alloy steels are known for their superior strength and toughness, making them ideal for applications that demand high durability and performance in harsh environments. They also have improved wear resistance, making them suitable for high-wear applications, such as heavy machinery or high-stress components.

Нержавеющая сталь

Stainless steel is well-known for its resistance to corrosion and its aesthetic appeal. This material is primarily composed of iron and chromium, forming a protective oxide layer that helps prevent rust and staining. Stainless steel is often chosen for its long-term durability and ability to withstand exposure to harsh chemicals and moisture.

Key Characteristics:

- Corrosion Resistance:Stainless steel’s most notable feature is its exceptional resistance to corrosion and staining, making it an ideal choice for applications exposed to moisture or chemicals.

- Durability:Stainless steel maintains its strength and integrity even in high temperatures and challenging environments.

- Aesthetic Appeal:Its sleek, polished finish is attractive and easy to maintain, making it ideal for products that require both functionality and a high-quality appearance.

Benefits: Stainless steel offers excellent longevity due to its corrosion resistance, which reduces the need for maintenance or frequent replacements. It also provides superior strength, impact resistance, and versatility, making it a popular choice for a variety of industries, including food processing, medical devices, and construction.

2. Key Considerations When Selecting Steel for Your Project

Choosing the right steel for your metal stamping project requires careful consideration of several factors. Here are the main considerations to keep in mind when selecting steel:

Project Requirements

Every project has unique demands. Understanding the specific requirements of your project—whether it’s related to structural integrity, precision, or resistance to harsh conditions—will help you determine the best steel type.

- Steel Properties:Pay attention to the steel’s mechanical properties, such as tensile strength, hardness, and flexibility, to ensure they align with your project’s needs. For example, projects requiring high tensile strength may benefit from alloy steel, while corrosion resistance may point you toward stainless steel.

- Functionality and Application:Consider how the steel will be used. Will it be exposed to high temperatures, chemicals, or mechanical stress? These factors should influence your decision when choosing the appropriate grade of steel.

Strength and Durability

Strength and durability are key factors in ensuring the success and longevity of your stamped components. The right steel must be able to perform under stress without failure.

- Tensile Strength:This refers to the material’s ability to resist pulling forces. Applications like structural beams or components under high stress demand steel with high tensile strength.

- Impact Resistance:Some applications require steel that can absorb and withstand impacts without fracturing. Steel types like alloy steel are often used for projects that will be subject to shock loads or heavy machinery.

- Longevity:Choosing steel with excellent durability ensures that your components will last longer, reducing the need for frequent replacements.

Коррозионная стойкость

For projects exposed to moisture, chemicals, or other corrosive elements, choosing the right steel with superior corrosion resistance is essential. Stainless steel, due to its high chromium content, is an excellent choice for environments that require protection against rust and degradation.

Cost and Budget Considerations

Balancing cost with performance is essential for managing your project’s budget. While stainless steel may offer superior properties, it also comes at a higher cost. Understanding your budget constraints and assessing the long-term value of different steel options will help ensure that you make the right decision.

- Material Costs:Different steel types come with varying price points. Stainless steel is more expensive than carbon steel but offers enhanced properties that might justify the cost for certain applications.

- Long-Term Value:Higher-quality steel may result in fewer maintenance needs, potentially saving you money in the long run.

3. The Role of Steel Composition and Heat Treatment

The composition of steel and its heat treatment process significantly influence its performance. Here’s how:

- Carbon Content:Steel with higher carbon content generally has better hardness and strength but may be less flexible. Depending on your application, this could be a key factor.

- Alloying Elements:Adding elements like chromium, nickel, and molybdenum can enhance properties such as wear resistance, corrosion resistance, and heat resistance.

- Heat Treatment:Processes like annealing, quenching, and tempering can be used to improve steel’s properties. For example, quenching increases hardness, while tempering balances hardness with toughness.

4. Industry Standards and Certifications

Ensuring that the steel meets industry standards is crucial for guaranteeing the performance and safety of your components. At Plantmetal, we adhere to strict standards like ASTM, ISO, and DIN to ensure that our materials meet the highest quality requirements. Additionally, certifications like Mill Test Reports (MTRs) and third-party certifications provide further assurance of the steel’s quality.

Conclusion

Choosing the right steel for your metal stamping project can be a complex process, but with the right knowledge and guidance, it becomes much easier. At Plantmetal, we specialize in helping you select the best steel for your unique requirements. Whether you’re looking for the durability of alloy steel, the corrosion resistance of stainless steel, or the cost-effectiveness of carbon steel, our team is here to assist you in making the most informed decision.

We understand that every project is different, and our experts are ready to discuss your specific needs to recommend the best materials for your metal stamping applications. Contact us today to discuss your project, and let us help you achieve the best results with the right steel selection.Feel free to reach out to us with any questions or concerns about your upcoming metal stamping projects. We’re here to help you every step of the way!