Обзор:

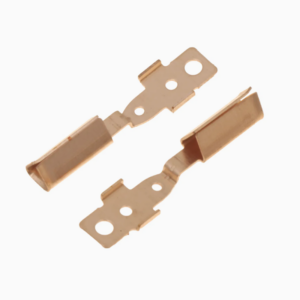

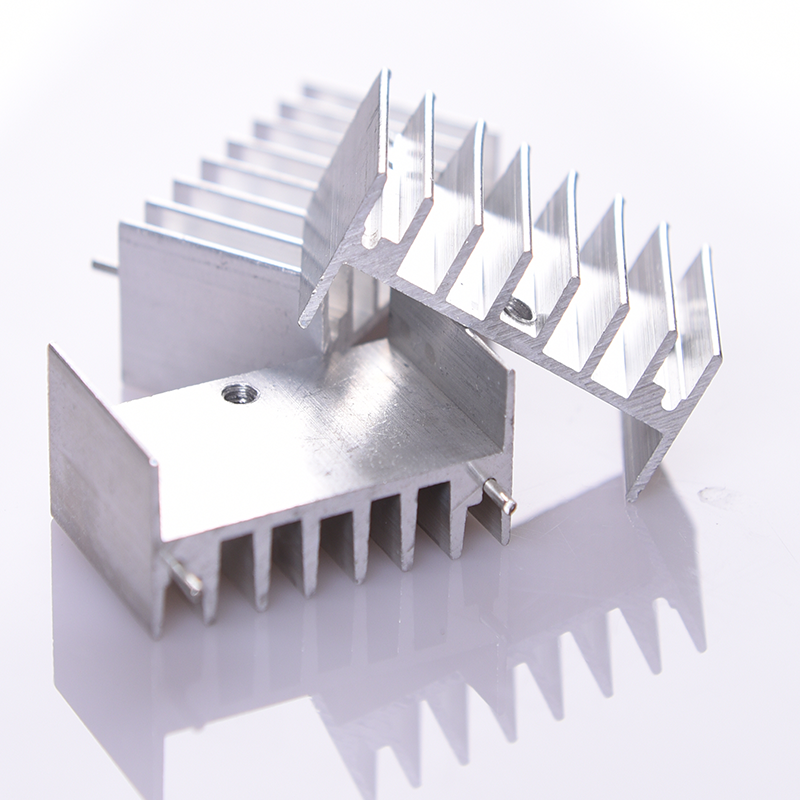

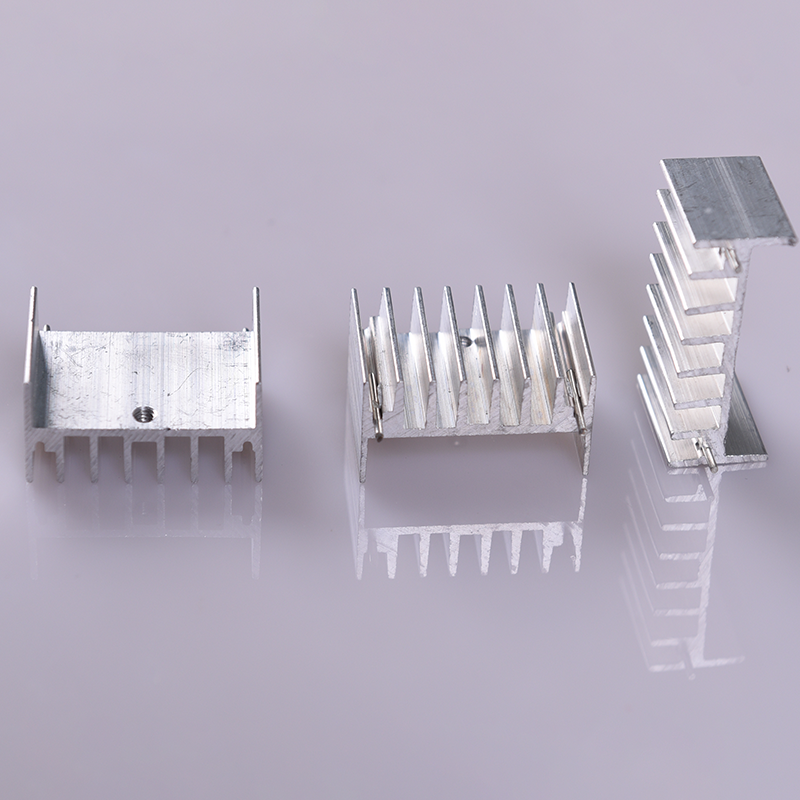

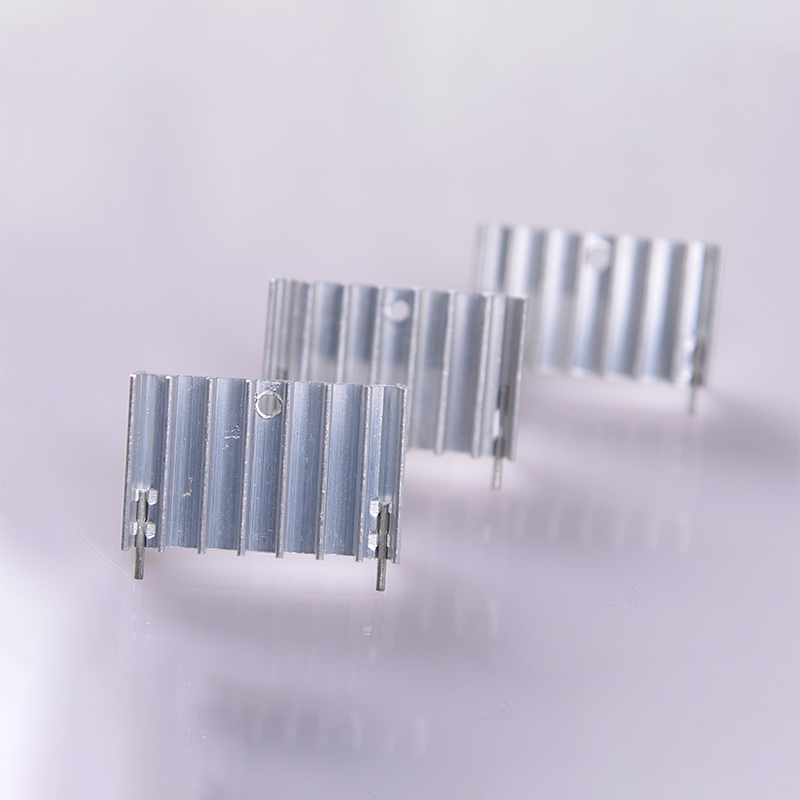

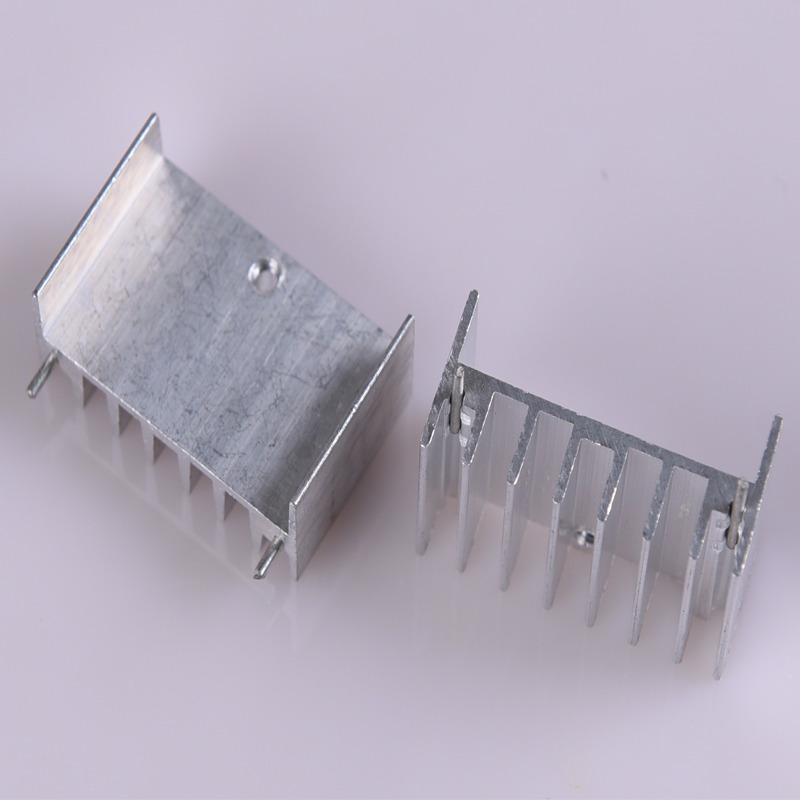

Штампованные радиаторы для компьютерных применений представляют собой важнейшее решение для теплоотвода, производимое с помощью передовых технологий, таких как экструзия, литье под давлением или прецизионная механическая обработка. Изготавливаемые из материалов с высокой теплопроводностью, таких как алюминий или медь, эти радиаторы спроектированы для эффективного рассеивания тепла, предотвращая тепловую перегрузку и обеспечивая оптимальную производительность и долговечность процессоров и графических процессоров. Мы также предлагаем услуги OEM-производства, предоставляя индивидуальные решения для теплоотвода, разработанные в соответствии с вашими конкретными потребностями и повышающие общую надежность и эффективность ваших систем.

Характеристики:

| Атрибут | Детали |

| Место происхождения | Сямынь, Китай |

| Время доставки | В течение 7 дней |

| Приложение | Отвод тепла компьютера |

| Форма | Пользовательский |

| Сервисы обработки данных | Гибка, Размотка, Сварка, Пробивка, Резка |

| Материал | Алюминиевый сплав |

| Настройка | Настраиваемый |

| Сертификация | ISO9001 / ROHS |

| Услуга | OEM |

| Цвет | Как на изображении; возможна индивидуальная настройка. |

Производственный процесс:

- Выбор материала: Высокопроводящие материалы, обычно алюминий или медь, выбираются исходя из требований к теплоотводу.

- Резка: Выбранный материал разрезается до требуемого размера и формы, часто с использованием лазерной резки или ЧПУ-обработки для достижения точных размеров.

- Формование: В зависимости от конструкции, радиатор формируется с помощью таких процессов, как экструзия, литье под давлением, штамповка или ковка, для создания необходимой структуры ребер для эффективного рассеивания тепла.

- Обработка поверхности: Для улучшения теплоотвода и защиты от коррозии радиатор подвергается обработке поверхности, такой как анодирование или нанесение гальванических покрытий.

- Assembly and Finishing: If the heat sink design includes multiple parts, they are assembled, followed by deburring, polishing, or coating as necessary to improve performance and aesthetics.

- Контроль качества: Проводится строгое тестирование, чтобы гарантировать соответствие радиатора стандартам теплопроводности, точности размеров и долговечности.

- Упаковка и доставка: После утверждения, радиаторы тщательно упаковываются и подготавливаются к отправке, что гарантирует их прибытие в идеальном состоянии.

Обработка поверхности радиатора

- Порошковое покрытие: На радиатор наносится прочный защитный слой с помощью электростатического напыления порошка, что повышает коррозионную стойкость и улучшает внешний вид.

- Пескоструйная обработка: Этот процесс придает поверхности шероховатость, создавая однородную текстуру, которая увеличивает площадь поверхности для лучшего рассеивания тепла и улучшает адгезию последующих покрытий.

- Покраска: Слой краски наносится для обеспечения дополнительной защиты от воздействия окружающей среды и улучшения внешнего вида радиатора.

- Фрезерованная поверхность: Радиатор сохраняет свою естественную металлическую отделку после механической обработки, без дополнительной обработки, обеспечивая чистый, полированный вид.

Каждая обработка повышает долговечность и тепловые характеристики радиатора, предлагая при этом возможности настройки внешнего вида и функциональности.

Показ Завода: