Описание:

Наше предприятие использует современное оборудование, включая четырехпозиционные и многопозиционные прессы, а также штамповочные прессы, для производства заказных литейных рамок, точно соответствующих вашим требованиям. Наша опытная команда конструкторов тесно сотрудничает с вами, чтобы гарантировать точное выполнение всех требований. Будучи сертифицированным производителем по стандартам ISO 9001, ISO 14001 и IATF 16949, мы стремимся поддерживать самые высокие отраслевые стандарты. Для обеспечения высочайшего качества мы осуществляем надежный сбор данных на каждом этапе производственного процесса и проводим тщательную окончательную проверку перед отправкой. Свяжитесь с нами сегодня, чтобы узнать, почему наш завод является идеальным партнером для ваших проектов по производству заказных литейных рамок.

Детали:

| Предмет | Детали |

| Место происхождения | Сямынь, Китай |

| Название бренда | OEM |

| Материал | Нержавеющая сталь, углеродистая сталь |

| Программное обеспечение для проектирования | UG, PROE, CAD |

| Сертификат | ИСО 9001:2015 |

| Толерантность | ± 0,002 мм – ± 0,05 мм |

| Процесс | Штамповка, пробивка |

| Завершить | Оцинковка, порошковое покрытие, покраска |

| Цвет | Пользовательский |

| MOQ | Возможен заказ небольшого количества |

| Упаковка | Пользовательский |

Производственный процесс:

-

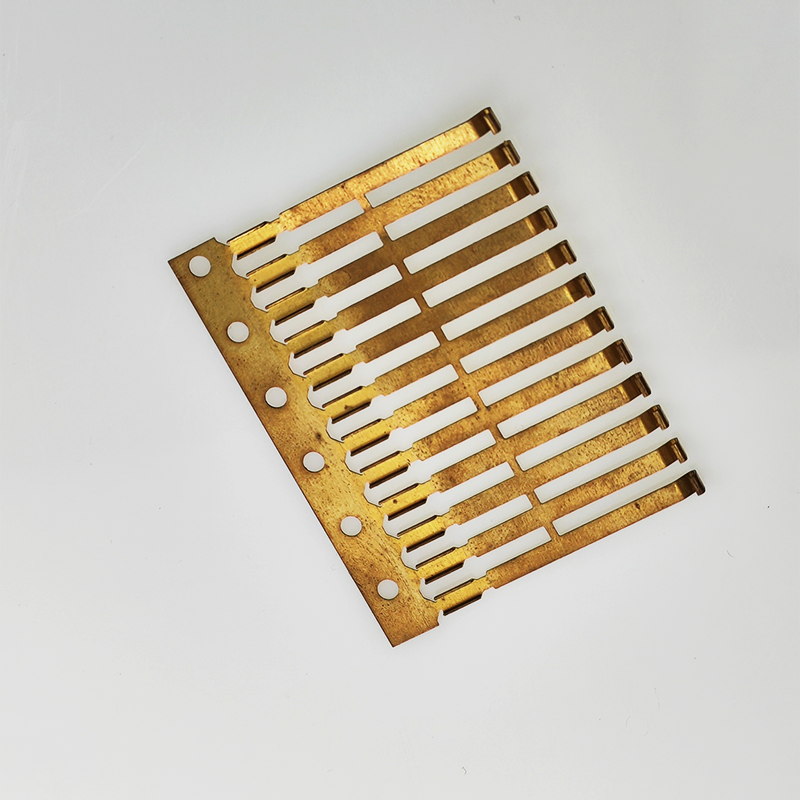

Выбор материала

– Используемые материалы: Обычно изготавливаются из таких материалов, как нержавеющая сталь, медь или латунь, которые выбираются благодаря их электропроводности, коррозионной стойкости и способности выдерживать высокие температуры.

-

Проектирование и оснастка

– Проектирование в САПР: Процесс проектирования начинается с использования передового программного обеспечения автоматизированного проектирования (САПР), такого как UG, PRO/E или CAD, для создания подробных спецификаций для выводной рамки.

– Изготовление оснастки: Прецизионные штампы изготавливаются с помощью ЧПУ обработки или электроэрозионной обработки (ЭЭО) для точного формирования выводов.

-

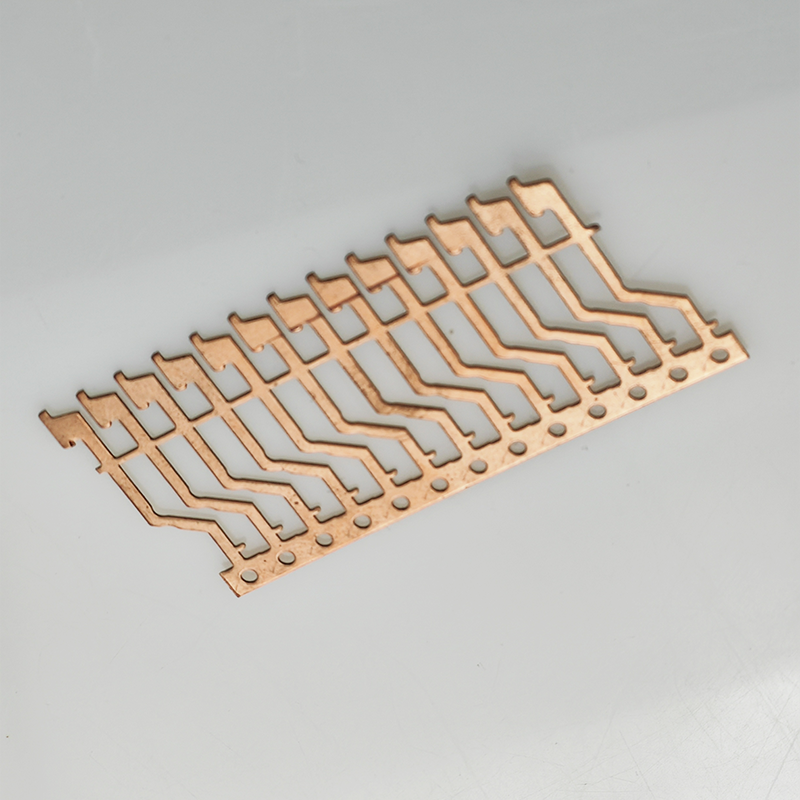

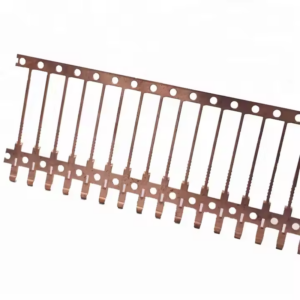

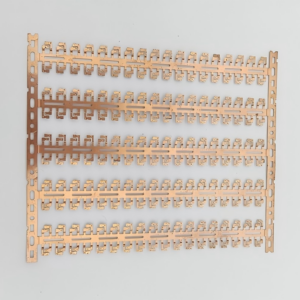

Штамповка

– Прогрессивная штамповка: В процессе штамповки используется многоступенчатый штамп для последовательного придания формы материалу, вырубки и формовки его в требуемую форму выводной рамки.

– Пробивка отверстий: Может потребоваться дополнительная пробивка отверстий для обеспечения точного расположения отверстий под светодиодные соединения.

-

Обработка поверхности

– Гальваническое покрытие: Лидфреймы покрываются тонким слоем золота, серебра, олова, никеля, цинка или меди для улучшения проводимости и защиты от коррозии.

– Лазерная гравировка: Лазерная гравировка может применяться для нанесения точной маркировки или идентификационных кодов на рамку выводов.

-

Осмотр

– Контроль качества: На протяжении всего производственного процесса выводы корпусов подвергаются строгому контролю качества, включая проверку точности размеров, качества поверхности и адгезии покрытия. Обычно применяемые методы контроля включают измерения на координатно-измерительной машине (КИМ) и визуальный осмотр.

-

Сборка (при необходимости) / Сборка (если требуется)

– Сборка: В некоторых случаях лидфреймы дополнительно собираются в готовые блоки, пригодные для использования в корпусировании светодиодов или интеграции в электронные устройства.

-

Упаковка и доставка

– Финальная упаковка: После того, как лидфреймы проходят контроль качества, они упаковываются в соответствии с требованиями заказчика. Доступны различные варианты упаковки, например, вакуумная упаковка или индивидуальная упаковка.

– Доставка: Готовая продукция затем доставляется заказчику в соответствии с согласованным графиком, зачастую с короткими сроками выполнения для срочных заказов.

Процесс Контроля Качества:

В компании Plantmetal качество является нашим главным приоритетом. Мы начинаем каждый проект с тщательной проверки осуществимости, чтобы гарантировать технологичность производства, а затем проводим исследование серийного выпуска на начальном этапе производства для подтверждения качества перед запуском полномасштабного производства. Это позволяет нашим командам тщательно контролировать производство и обеспечивать бесперебойную работу.

Мы используем передовые системы технического зрения с камерами, работающими как в режиме реального времени, так и вне производственной линии, а также сенсорные технологии для контроля каждой детали в процессе производства, обеспечивая 100% качество и отсутствие дефектов. Наша система менеджмента качества, сертифицированная по ISO, поддерживаемая инициативами по постоянному совершенствованию, гарантирует, что каждая деталь соответствует самым высоким стандартам.

Понимая, что дизайн выводной рамки требует индивидуальных спецификаций, мы предлагаем специализированные решения для критически важных применений. Обладая богатым опытом в производстве высокоэффективных выводных рамок, Plantmetal является вашим надежным партнером в обеспечении точности и качества при их изготовлении.

Наш завод:

Мы эксплуатируем широкий ассортимент оборудования и установок, чтобы обеспечить производство продукции высочайшего качества. Наши мощности оснащены 25 штамповочными прессами с усилием от 25 до 300 тонн, высокоточным электроэрозионным оборудованием (EDM), шлифовальными станками, инструментами для сварки и полировки, а также ультразвуковыми системами очистки.

В дополнение к нашим производственным возможностям, мы предлагаем различные процессы металлопокрытия, чтобы улучшить долговечность, внешний вид и функциональность нашей продукции штамповки металла. Среди них: гальваническое покрытие, цинковое покрытие, никелирование, хромирование и анодирование. Наши современные мощности для нанесения покрытий обеспечивают равномерные покрытия, устойчивость к коррозии и соответствие отраслевым стандартам.

Это сочетание профессиональных и автоматизированных производственных линий, передового механического оборудования, строгих мер контроля качества и высококачественных процессов гальванического покрытия обеспечивает поставку штампованных металлических изделий высочайшего стандарта.