Обзор:

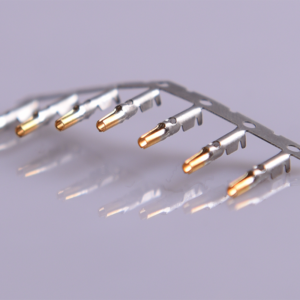

Наши серебряные электрические контакты тщательно разработаны и изготовлены в соответствии с высочайшими стандартами качества и надежности. Используя передовую технологию сварки в штампе, мы обеспечиваем исключительную стабильность и однородность продукции на всех этапах производственного процесса.

Эти серебряные электрические контакты не только демонстрируют превосходные эксплуатационные характеристики, но и обладают значительным экономическим преимуществом. Благодаря применению технологии сварки в штампе, мы оптимизируем процесс производства, что позволяет изготавливать продукцию в больших объемах, снижая затраты и повышая общую эффективность производства.

Детали:

| Спецификация | Детали |

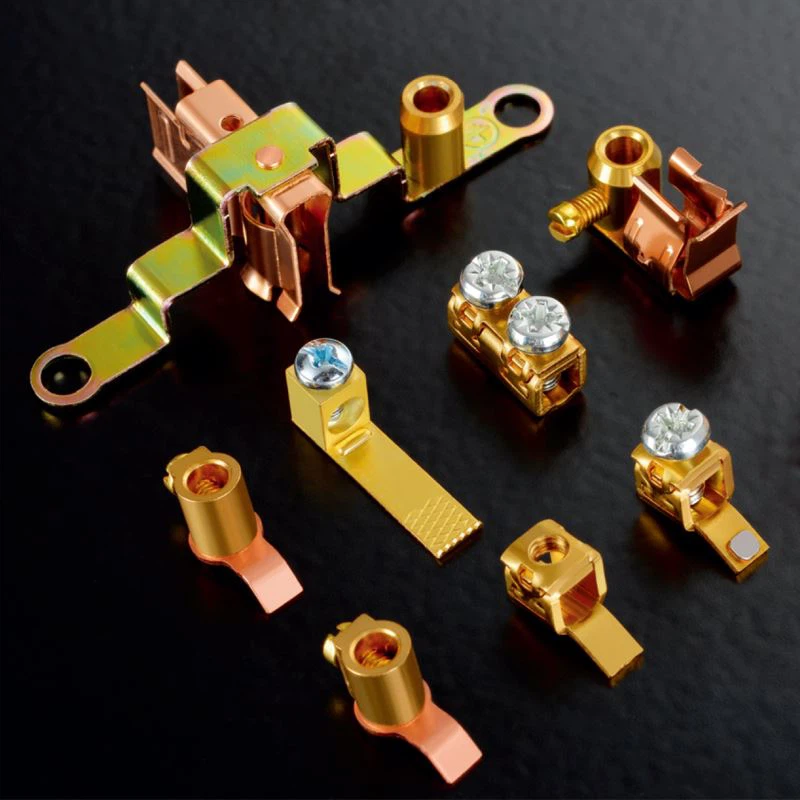

| Craftsmanship | Штамповка, ЧПУ (числовое программное управление) |

| Завершить | Покрытие (Гальваническое покрытие, никелирование и т.д.) |

| Цена | Ценообразование завода в реальном времени |

| Упаковка | Внутри: Пластиковый пакет и пенополиэтилен (PE Foam); Снаружи: Картонная упаковка |

| Услуги | Доступны OEM-услуги для индивидуальных дизайнов и спецификаций. |

| Место происхождения | Сямынь, Китай |

| Варианты материалов | Алюминий, нержавеющая сталь, латунь, медь, пластик и т.д. |

| Варианты цветов | Белый, Чёрный, Красный, Синий, Серебристый, Золотой, Доступны индивидуальные цвета |

| Сертификаты | ISO9001:2015, сертифицировано SGS |

| Производственная мощность | 5 000 единиц в день (на одну машину) |

| Время выполнения | 7–15 дней в зависимости от размера и сложности заказа |

| Тестирование | 100% инспекция, инспекция третьей стороной по запросу |

| Варианты доставки | DHL, FedEx, UPS, TNT, EMS, морским транспортом, грузовиком или поездом |

Производственный процесс:

- Выбор материала: Высокочистое серебро и другие сплавы тщательно отбираются для обеспечения превосходной электрической проводимости, долговечности и устойчивости к коррозии.

- Проектирование штампов и оснастки: Точные конструкции штампов разрабатываются с использованием современного программного обеспечения CAD/CAM, чтобы обеспечить оптимальную форму компонентов электрических контактов. Затем штампы изготавливаются с высокой точностью с помощью ЧПУ-обработки или других передовых технологий.

- Штамповка и Формирование: Сырьевые материалы обрабатываются с использованием высокоточных штамповочных машин, формируя базовую форму электрических контактов. Этот процесс тщательно контролируется для обеспечения постоянных размеров и качества.

- Сварка в прессе (In-Die Welding): Для определённых конструкций используется технология сварки в прессе, которая позволяет соединять компоненты во время процесса штамповки. Это обеспечивает прочные, бесшовные соединения и устраняет необходимость в дополнительных этапах сборки.

- Поверхностная обработка: Электрические контакты проходят различные виды поверхностной обработки, такие как гальваническое покрытие, полировка или нанесение защитного слоя, для повышения их долговечности, электрической проводимости, а также устойчивости к износу и коррозии.

- Инспекция и тестирование: Каждая партия серебряных металлических электрических контактов проходит тщательное тестирование, включая проверку размеров, визуальный осмотр и тестирование электрических характеристик, чтобы гарантировать соответствие спецификациям и отраслевым стандартам.

- Упаковка: После утверждения электрические контакты тщательно упаковываются, чтобы предотвратить повреждения во время транспортировки и гарантировать их доставку в идеальном состоянии.

- Доставка: Готовый продукт затем отправляется клиентам, с возможностью выбора ускоренной или стандартной доставки в зависимости от требований клиента.

Варианты обработки поверхности:

Анодирование: Обеспечивает прочное, устойчивое к коррозии покрытие с повышенной поверхностной твердостью, идеально подходящее для алюминиевых компонентов.

Порошковое покрытие: Обеспечивает прочное, высококачественное покрытие, устойчивое к сколам, царапинам и выцветанию, доступное в широком ассортименте цветов.

Покраска: Обеспечивает гладкое, эстетически приятное покрытие с отличной адгезией, идеально подходящее как для защитных, так и для декоративных целей.

Пескоструйная обработка: Создает равномерную матовую текстуру на металлических поверхностях, улучшая их внешний вид и подготавливая их к дальнейшей отделке.

Полировка: обеспечивает высокоглянцевое, зеркальное покрытие, которое улучшает внешний вид поверхности, придавая ей гладкую и изысканную текстуру.

Показ Завода: