Description:

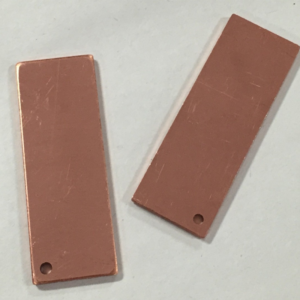

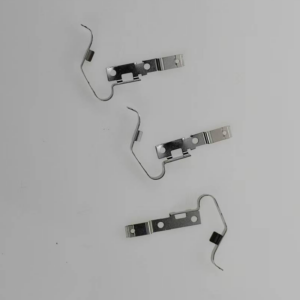

Silver-plated electronic stamped contacts for electric control systems are high-precision components crafted through advanced stamping and electroplating processes. These contacts are typically made from premium metals like copper or brass and then coated with a silver layer to enhance conductivity, corrosion resistance, and overall durability.

In electric control systems, silver-plated contacts improve electrical performance by minimizing contact resistance and ensuring reliable operation in high-voltage and high-frequency environments. They also provide excellent resistance to oxidation and wear, contributing to long-term system stability.

Our factory offers OEM customization services, including a wide range of sizes, materials, and surface treatment options to suit the specific requirements of your electric control applications. With state-of-the-art equipment and expert engineering, we deliver precision-engineered products that meet the highest quality standards.

Features:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Size | Custom |

| Sample | Available |

| Material | Copper-1100, Copper-5191, Brass-6265, Brass-7275 |

| Shipment Ways | Express Freight / Air / Sea |

| Certificate | ISO9001:2008, ROHS |

| Thickness | 0.1-0.5mm |

| Minimum Quantity | According to your requirement |

| Usage | Electric Control System |

Other Surface Treatment Options:

- Gold Plating: Ideal for high-performance electronics, gold plating improves electrical conductivity, enhances corrosion resistance, and adds a premium aesthetic finish.

- Nickel Plating: This treatment provides superior durability, safeguarding parts against wear and corrosion, which significantly extends the service life of components.

- Tin Plating: Often used for cost-effective protection, tin plating enhances corrosion resistance and improves solderability, making it a popular choice for various applications.

Operational Process:

- Material Selection: We begin by selecting premium metals, such as copper-1100, copper-5191, brass-6265, or brass-7275, known for their exceptional electrical conductivity and durability, ensuring optimal performance in electronic applications.

- Stamping: Using advanced progressive dies and precise tooling, the selected material is stamped into the required contact shape. This process guarantees tight tolerances, consistent dimensions, and uniformity across all parts.

- Surface Preparation: The stamped contacts undergo a meticulous cleaning process to remove any contaminants, oils, or impurities. This ensures the surface is perfectly prepared for the electroplating step.

- Silver Plating: A thin, uniform layer of silver is applied to the contacts through electroplating. This enhances their conductivity, corrosion resistance, and overall durability, ensuring the components perform reliably in demanding environments.

- Inspection & Testing: After plating, the contacts undergo a thorough quality control process, including electrical conductivity tests, dimensional verification, and visual inspections. These steps ensure all parts meet stringent standards for use in electric control systems.

- Packaging & Shipping: Once the contacts pass all inspections, they are carefully packaged and prepared for shipping according to customer specifications. We offer flexible shipping options, including expedited, air, or sea delivery, to meet the customer’s needs.

Quality Control Process:

Our quality control process for silver-plated electronic stamped contacts is designed to uphold the highest standards and consistently exceed customer expectations. We follow stringent, well-documented procedures and operate a fully equipped inspection department to ensure each component meets precise specifications. All incoming raw materials are meticulously tracked for traceability, and our inspection instruments are regularly calibrated to ensure accuracy and consistency.

To further ensure compliance, we offer analysis reports upon request, which provide an additional layer of verification. Any non-conforming parts are immediately segregated for thorough evaluation, and root cause analysis is conducted to identify underlying issues. Corrective actions are swiftly implemented to prevent future occurrences.

We are committed to continuous improvement, encouraging our team to propose enhancements in processes, materials, and suppliers. This proactive approach to quality control guarantees that our silver-plated contacts deliver exceptional performance and reliability, making them ideal for use in demanding electric control systems.