Overview:

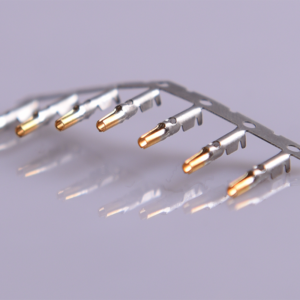

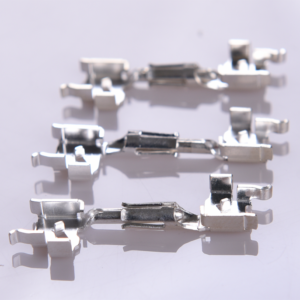

Our high-quality Stainless Steel Stamped Terminal Connectors, designed for precision and reliability in the Medical Equipment Industry. Ideal for Surgical Equipment, these connectors offer excellent corrosion resistance and durability. With OEM services and customization options, we provide tailored solutions to meet your specific requirements. Contact us today to learn more.

Characteristics:

- Certification: ROHS, ISO9001

- Customization: Available

- Material: Stainless Steel

- Surface Finish: Electroplating

- Sample Lead Time: 5-40 days, depending on the product

- Drawing Format: 2D, 3D Drawing Software

- Quality Control: 100% inspection before shipment

- Shipping Method: FOB, CIF, DDP, and more

- Transport Packaging: Blister packaging, poly bag, foam, wood box, custom options

- Specification: Customized

- Trademark: OEM

- Origin: Xiamen, China

- Production Capacity: 100,000,000 PCS/year

Production Process:

- Material Selection: High-quality stainless steel is chosen for its superior strength, corrosion resistance, and biocompatibility, making it suitable for medical and surgical applications.

- Die Design and Tooling: Custom dies are designed and manufactured in-house to ensure precise stamping of connectors. The tooling is optimized for high accuracy and repeatability.

- Stamping Process: The stainless steel sheets are fed into high-tonnage stamping presses, where the custom-designed dies form the terminal connectors with tight tolerances and consistent quality.

- Electroplating: After stamping, the connectors undergo an electroplating process to enhance surface durability, provide corrosion resistance, and improve electrical conductivity, ensuring long-term reliability in medical devices.

- Inspection and Quality Control: Each connector is thoroughly inspected to meet strict medical industry standards. This includes dimensional checks, surface quality inspections, and functional tests to ensure the connectors will perform reliably in surgical equipment.

- Packaging: The finished connectors are carefully packaged in sterile and protective materials, such as blister packs or custom packaging, to ensure safe shipping and handling.

Quality Assurance:

The quality control process involves rigorous testing and inspection to ensure precision, durability, and reliability. Each connector undergoes thorough dimensional checks using calipers, projectors, and a 2.5D measuring machine to confirm tight tolerances. The connectors are also inspected for surface quality using height gauges and plug gauges to ensure proper fit and function. For corrosion resistance, salt spray test equipment is employed to simulate harsh environmental conditions, while high temperature and humidity equipment is used to assess performance under extreme conditions. These comprehensive testing methods ensure that all terminal connectors meet the stringent standards required for surgical equipment applications, guaranteeing long-lasting performance and safety.

Why Choose Us?

Customized OEM Solutions and Complete Assembly Services

With over 20 years of experience, we specialize in providing tailored OEM solutions and comprehensive assembly services. Utilizing cutting-edge manufacturing technologies, we ensure that each product is meticulously crafted to meet your precise specifications, achieving the highest standards of quality and performance.

Diverse Product Offerings

Our extensive product portfolio includes precision-stamped components, CNC-machined parts, springs, shafts, fasteners, and more. As a trusted full-service provider, we manage every phase of your project—from initial concept and design to final production—ensuring smooth execution and exceptional results at every stage.

Industry-Recognized Certifications and Expertise

As a reliable Tier 2 supplier, we comply with the most stringent industry standards, with certifications such as RoHS and HE compliance confirming our commitment to delivering products that meet global regulatory and quality requirements.

Commitment to Quality Excellence

Certified to ISO 9001:2015 and IATF 16949 standards, our quality management system ensures that each component is produced with unmatched precision, durability, and consistency. We are dedicated to exceeding expectations at every stage of production, from design to final delivery.