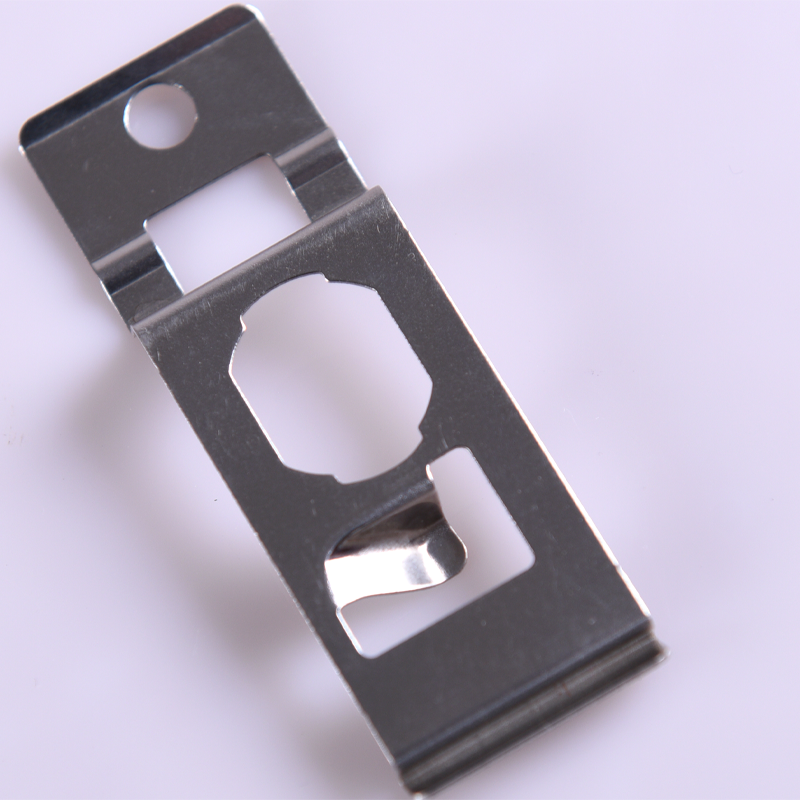

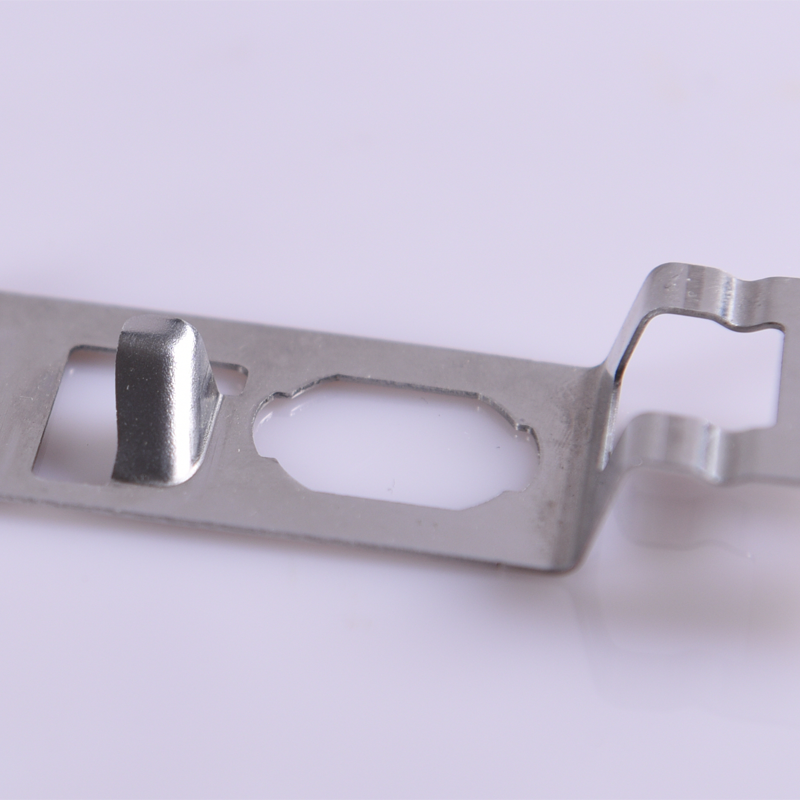

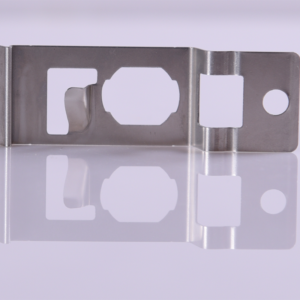

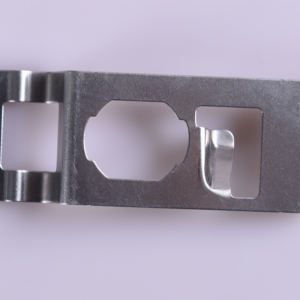

Our high-quality custom shields are expertly crafted to meet the diverse needs of various industries, offering reliable protection and performance across a wide range of applications. Manufactured using advanced processes like precision stamping and cutting, our shields are designed to provide superior durability, electrical insulation, and shielding against electromagnetic interference (EMI). We offer a comprehensive range of customization options, including size, shape, material, and finish, ensuring that each shield is perfectly tailored to your specific requirements. Whether you need shields for electronic devices, automotive components, or industrial equipment, we can deliver a solution that meets your exact specifications. Contact us today to discuss your custom shield needs and receive a competitive price.

Manufactured using advanced processes like precision stamping and cutting, our shields are designed to provide superior durability, electrical insulation, and shielding against electromagnetic interference (EMI). We offer a comprehensive range of customization options, including size, shape, material, and finish, ensuring that each shield is perfectly tailored to your specific requirements. Whether you need shields for electronic devices, automotive components, or industrial equipment, we can deliver a solution that meets your exact specifications. Contact us today to discuss your custom shield needs and receive a competitive price.

Materials and Customization

Materials: Carbon spring steel, alloy spring steel, stainless spring steel, copper alloy, nickel alloy

Customization: Sizes and dimensions can be tailored according to customer requirements

Applications: Network devices, communication equipment, computers, household appliances, distribution systems, educational toys, among others

One-Stop Service for Metal Stamping Parts

– Design and Prototyping: We provide end-to-end design services, including CAD modeling and prototyping, to ensure your metal stamping parts meet precise specifications and functionality requirements.

– Tooling and Die Development: Our facilities handle the complete tooling and die creation process, utilizing advanced technology to produce high-precision tools and dies that ensure consistent part quality.

– Metal Stamping Production: We offer comprehensive metal stamping services, capable of handling a wide range of materials and sizes. Our equipment supports both high-volume production and custom orders with exceptional accuracy.

– Surface Treatment: Enhance the performance and appearance of your parts with our surface treatment options, such as electroplating, coating, and polishing, tailored to meet your specific requirements.

– Quality Control: Our rigorous quality control process includes thorough inspections and testing to ensure that every part adheres to the highest standards of precision and durability.

– Custom Packaging and Logistics: We provide custom packaging solutions and manage logistics to deliver your stamped parts safely and efficiently, ensuring they arrive on time and in optimal condition.

– Post-Production Support: Our service extends beyond manufacturing, offering ongoing support to address any issues, provide maintenance, and ensure that your needs are continuously met.