Overview:

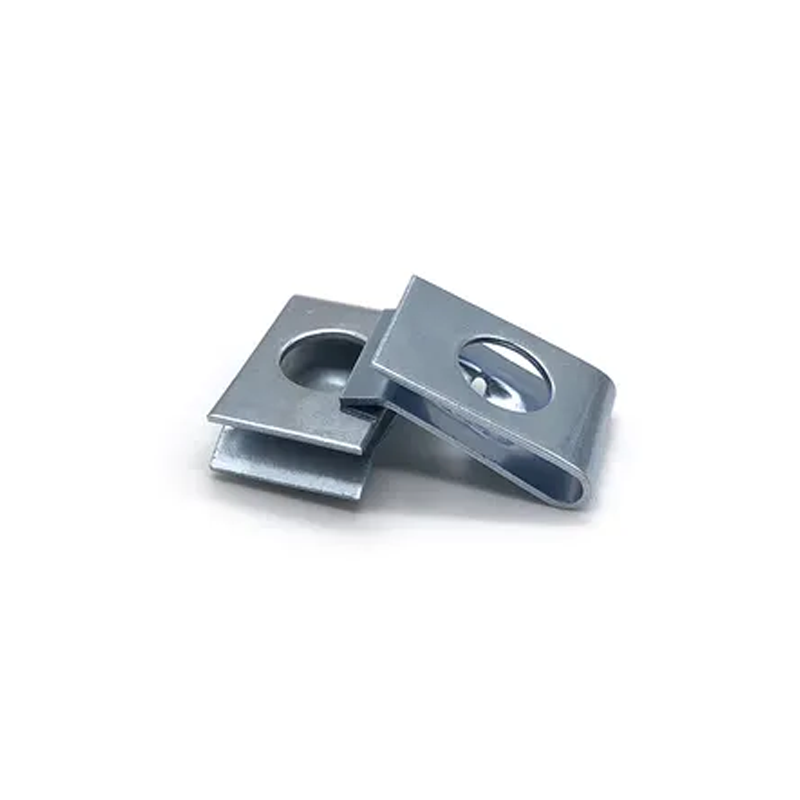

SUS631 flat spring fastener clips are made from high-strength, corrosion-resistant martensitic stainless steel, commonly manufactured through metal stamping. These clips are widely used in industries like automotive, electronics, and industrial equipment, offering reliability and performance.

At Plantmetal, we specialize in custom SUS631 clips in various shapes and sizes, with secondary services such as vacuum hardening, oil quenching, and Austempering. As a one-stop supplier, we offer comprehensive solutions, including unlimited plating options, ensuring precision and timely delivery for all your custom clip needs.

Details:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Thickness | 0.1mm – 12mm |

| Materials | Zinc, Aluminum, Copper, Steel, Powder Coating, etc. |

| Process | Punching, Stamping, Bending, Riveting, etc. |

| Technology | Metal Stamping |

| Testing | Salt Spray |

| OEM | Accepted |

| Certification | ISO 9001:2008, IATF16949, ROHS |

Quality Assurance:

At Plantmetal, ensuring the highest quality of our fasteners and clips is our top priority. We begin each program with a thorough feasibility review to confirm that the parts are manufacturable. A run-at-rate study is conducted during the first production run to guarantee quality before scaling up. This allows our quality and production management teams to closely monitor controls, ensuring smooth operations. Once the initial batch meets quality standards, production continues.

Our quality management system incorporates advanced technology, continuous improvement initiatives, and a dedicated quality lab. We use in-line and off-line camera vision systems and sensors, custom-designed for each production run. These vision systems work in sync with our stamping machinery to meticulously inspect part features and dimensions through automated imaging. This stringent quality control ensures that all fasteners and clips produced meet the highest standards, with zero defects.

Strengthen your application with precision fasteners and clips from our factory. With a committed team, cutting-edge equipment, and unmatched quality control, we guarantee reliable products delivered on time.

Production Process:

- Material Selection: High-quality SUS631 stainless steel is chosen for its excellent mechanical properties, such as strength, corrosion resistance, and durability.

- Stamping: The selected material is fed into a progressive die stamping press, which uses high-pressure stamping to form the flat spring clips to the desired shape and size. This process ensures consistency and precision.

- Bending: After stamping, the clips are bent into their final shape using a bending machine. This step is critical to achieving the required functionality, particularly for the spring action of the clips.

- Heat Treatment: The clips are subjected to heat treatment processes such as hardening or tempering to improve their mechanical properties, including strength and flexibility.

- Surface Finishing: To enhance corrosion resistance and improve the aesthetic appearance, the clips undergo surface treatments such as zinc plating, nickel plating, or other protective coatings.

- Quality Control: Every batch of clips undergoes stringent quality control checks, including dimensional inspections, material testing, and visual inspections to ensure they meet required specifications.

- Packaging: Once the clips pass inspection, they are packaged in custom packaging to prevent damage during shipping and handling, ensuring they reach customers in perfect condition.

Our Factory:

We operate a fully equipped manufacturing facility with a range of advanced machinery to guarantee top-tier production quality. Our plant includes 25 punch presses, from 25 to 300 tons, precision wire EDM machines, grinding equipment, welding and polishing tools, as well as ultrasonic cleaning systems.

To further enhance the durability, appearance, and performance of our stamped metal products, we provide various plating options such as electroplating, zinc, nickel, chrome plating, and anodizing. Our cutting-edge plating facilities ensure uniform finishes, excellent corrosion resistance, and compliance with industry standards.

This combination of advanced automation, high-quality machinery, and stringent quality control processes enables us to deliver superior metal stamping products consistently.