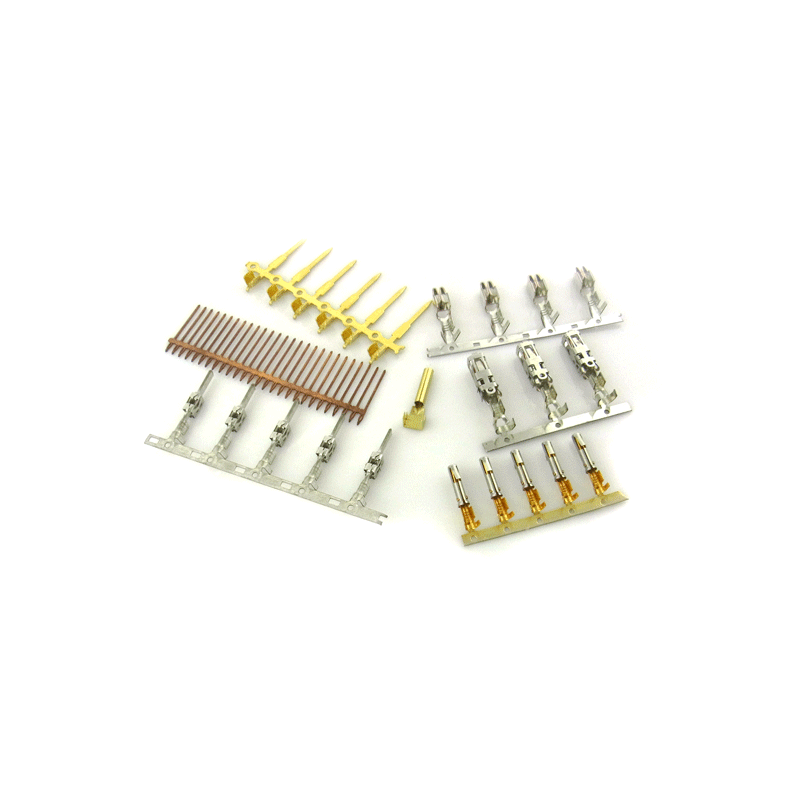

Terminal Stamping for Automotive Application Overview

Our precision stamping services facilitated the production of one million automotive terminals, meeting the industry’s high standards for quality and performance. These terminals underwent bright tin plating, which was applied through a reel-to-reel process. This method not only ensured a uniform tin coating for enhanced corrosion resistance but also delivered significant cost savings for our customer. The result is a durable and reliable terminal, designed to withstand the demanding conditions of automotive applications, while maintaining superior electrical conductivity and longevity.

Surface Treatment Options:

1.Anodization

Enhances aluminum’s natural oxide layer for improved corrosion resistance and wear properties, available in various colors.

2.Powder Coating

Durable finish resistant to chips, scratches, and fading, offering extensive color and texture choices.

3.Electroplating

Deposits metal layers like nickel, zinc, or chrome to enhance appearance, corrosion resistance, and surface hardness.

4.Passivation

Chemical treatment to boost corrosion resistance without altering appearance.

5.Polishing

Creates a smooth, reflective surface for improved aesthetics.

6.Brushing

Uniform satin texture that hides fingerprints and minor scratches.

7.Painting

Customizable colors and protective coating.

8.Sandblasting

Creates a textured finish for enhanced adhesion and unique appearance.

Custom Process:

Supply Requirements Assessment:

– Evaluate and determine specific product requirements as per customer specifications and preferences.

– Collaborate with customers to gather detailed information and ensure alignment with desired outcomes.

Sample Validation:

– Conduct thorough validation of product samples to verify compliance with customer expectations and quality standards.

– Ensure that samples meet all specified criteria before proceeding with mass production.

Production and Quality Assurance:

– Execute comprehensive production processes while adhering to established quality standards and protocols.

– Implement rigorous quality inspection procedures at every stage of production to maintain product integrity and consistency.

Packaging and Logistics:

– Strategically package finished products according to customer preferences and shipping requirements.

– Organize efficient shipping and logistics processes to ensure timely and secure delivery to customers’ specified locations.