Overview:

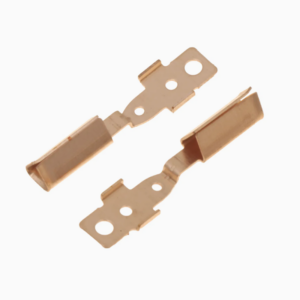

Our tin-plated copper busbars are made from C110 copper, precision-engineered using metal stamping and CNC bending. Available with bare copper, tin plating, nickel plating, or silver plating finishes, and insulated with PVC, PE heat shrink tubing, or epoxy powder coating, these busbars can be customized in size and shape. Designed for use in distribution boards, they improve electrical conductivity, eliminate wiring errors, and reduce assembly costs, with design and prototype assistance available from our expert technicians.

Characteristics:

| Feature | Details |

| Processing Type | Metal Stamping |

| Material | Copper |

| Mould | Simple Single Process Dies |

| Surface Processing | Tin-Plated |

| Fine Blanking | Open |

| Industry | Electronic Parts |

| Tolerances | ±0.01mm |

| Customized | Yes |

| Finish | Bare, Tin Plating, Nickel Plating |

| Insulation | PE Heat Shrink Tube, PVC, Epoxy Powder |

| Size | Customized |

| Transport Package | Custom |

| Specification | Customized |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 10,000 PCS/Day |

Other Surface Treatment Options:

- Bare Copper– No coating, showcasing the natural copper finish for direct use or further processing.

- Nickel Plating– A durable and corrosion-resistant finish that enhances the longevity and conductivity of the copper busbar.

- Silver Plating– Provides superior conductivity and resistance to oxidation, ideal for high-performance electrical applications.

- Epoxy Powder Coating– A protective, insulating finish that prevents corrosion and is commonly used in environments requiring electrical insulation.

Quality Assurance:

At Plantmetal, quality is our core focus. Each project begins with a thorough feasibility review to ensure manufacturability, followed by a run-at-rate study to verify quality before full-scale production. This enables our quality and production teams to monitor and maintain optimal process control, ensuring smooth manufacturing and conforming parts.

Our quality management system integrates advanced technologies, including custom-designed camera vision systems and sensors, to inspect part features and dimensions with precision. This system, working in tandem with our stamping machinery, ensures 100% defect-free production.

Plantmetal is ISO 9001 and IATF 16949 certified, demonstrating our commitment to the highest industry standards. With a focus on performance and reliability, we provide copper busbars and other stamped components tailored to meet your unique needs.

Why Choose Us?

- Factory-direct pricing for cost-effective solutions.

- Commitment to quality. We conduct thorough first article, in-process, and final inspections to ensure superior quality.

- Exceptional customer support. Our dedicated specialists oversee pre-sales, quality control, logistics, and after-sales service.

- Prompt delivery with comprehensive one-stop service.

Our Factory:

We operate a fully equipped facility to ensure top-tier production quality. Our plant includes 25 punch presses ranging from 25 to 300 tons, precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems.

In addition to robust manufacturing capabilities, we offer a wide range of metal plating options to improve the durability, appearance, and functionality of our stamped products. These include electroplating, zinc, nickel, chrome plating, and anodizing. Our advanced plating facilities guarantee consistent finishes, enhanced corrosion resistance, and compliance with industry standards.This blend of automated production lines, cutting-edge equipment, stringent quality controls, and superior plating techniques ensures we deliver metal stamping products of the highest quality.